Unlock efficiency and precision across all your CNC machines with tooling designed for universal fit.

What Are Brand - Agnostic Tooling Solutions?

If your shop runs on multiple machine brands, sticking to one OEM’s tooling is like racing with one shoe on

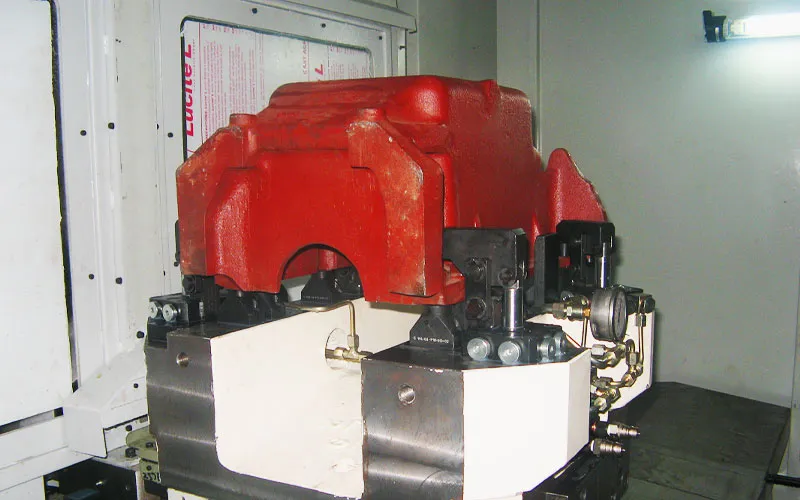

Brand-agnostic tooling lets you break free from rigid, overpriced, and often delayed OEM-specific tools. Instead, you get custom-engineered toolings lets you achieve flexible ,afforadable and fastest delivery on any OEM VMC/HMC machine no matter the make, model, or complexity.

You don’t adapt your workflow to the tools. We design the tools to match your workflow.

You're not tied to a single brand’s pricing, lead times, or limitations. Our tools fit your machines perfectly.

We cut down your tooling lead times, simplify replacements, and reduce inventory overhead, all without compromising on quality.

We study your parts, tolerances, and cycle times to build tools that work the way your floor actually runs.

From European to Japanese to Asian to Indian, we integrate seamlessly across multi-brand

Our toolings are high precision, have a longer tool life, and have no hidden premiums. And that’s helps you cut down your cost significantly.

Trusted by manufacturers across sectors where precision, uptime, and traceability matter most.

Yes, 100%. Our team reverse-engineers your current setup and delivers drop-in compatible solutions without any rework or machine alterations.

m2nxt is focused on tooling solutions to meet your operational needs and affordable

Yes. In many cases, our tooling offers even better life cycles, and we back it up with testing data and ongoing support.

Absolutely. We offer on-site assistance, training, and technical support to ensure smooth adoption with minimal downtime.

Yes. Once your specs are locked, we ensure fast reorders with predictable lead times, without the delays tied to imports.

With m2nxt, you don’t just monitor - you understand, Optimized, and excel.