Rebuild, Reinvent, and Get Back to Production — Without Starting Over

What is Directed Energy Deposition (DED)?

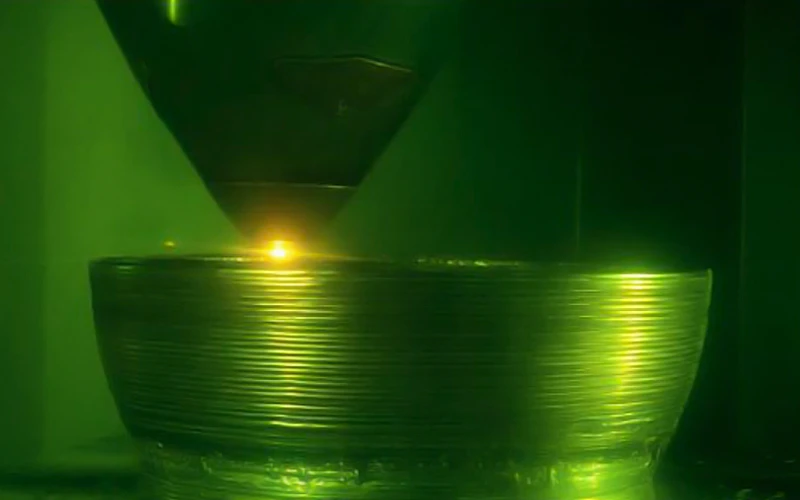

Directed Energy Deposition (DED) is an advanced metal additive manufacturing technology that fabricates or repairs parts by depositing material in the form of metal wire or powder - using a focused energy source such as a laser or electric arc.

Unlike traditional methods, DED adds material only where it's needed. You can repair, rebuild, or create metal parts with less waste, more speed, and lower costs.

If you're facing

DED is widely used across aerospace, automotive, power, marine, and tooling sectors where turnaround time, traceability, and precision are essential.

LDED uses a focused laser to melt metal powder or wire and deposit it with high precision, layer by layer. It is ideal for detailed parts, fine repairs, and complex shapes with minimal waste.

View More

Arc DED uses electrically generated heat through the electric arc to melt metal wire and build parts fast, making it ideal for large, heavy-duty components.

View MoreTrusted by manufacturers across sectors where precision, uptime, and traceability matter most.

DED works with a wide range of metals — including titanium, stainless steel, aluminium, Inconel, copper alloys, tool steels, and cobalt-chrome. It also supports composite and functionally graded materials. Whether you're printing new parts or repairing old ones, there's a good chance your material is covered.

DED and PBF are both metal additive manufacturing processes, but they work in completely different ways and serve different purposes.

DED uses a focused energy source (like a laser or arc) to melt metal wire or powder directly onto a part, making it perfect for repairs, large parts, and functional upgrades.

PBF, on the other hand, spreads a thin layer of powder and melts it selectively with a laser, which makes it better for small, complex, high-detail components.

Here’s a quick side-by-side to help you understand how they compare:

| Aspect | Directed Energy Deposition (DED) | Powder Bed Fusion (PBF) |

|---|---|---|

| Process | Deposits and melts material (powder or wire) directly onto a substrate using a focused energy source (laser, electron beam, or plasma arc). | Spreads a thin layer of powder on a build platform, selectively melting it with a laser or electron beam in a powder bed. |

| Material Delivery | Material is fed via a nozzle as powder or wire, built layer by layer. | Powder spread evenly across a bed, melted in specific areas. |

| Precision | Lower resolution, suited for large or less intricate parts. | High precision, ideal for complex, detailed, and small components. |

| Build Volume | Flexible, can handle large parts or repairs on existing components. | Limited by the size of the powder bed, typically smaller parts. |

| Applications | Repairing parts (e.g., turbine blades) and adding features and large-scale components in aerospace, energy, and automotive. | High-precision parts like medical implants, aerospace components, and intricate geometries. |

| Material Versatility | Supports metals (titanium, steel, and nickel alloys), wires, and some composites; excels in multi-material deposition. | Primarily metals (stainless steel, titanium, aluminium); limited to powder-based materials. |

| Post-Processing | Often requires machining for surface finish but minimal powder handling. | Extensive post-processing to remove excess powder and improve finish. |

| Speed | Faster for large parts or repairs due to higher deposition rates. | Slower due to layer-by-layer powder spreading and melting. |

| Waste | Minimal waste, especially with wire-fed systems, as material is added only where needed. | Higher waste due to unmelted powder, though recyclable. |

Here's a quick comparison based on the kind of parts you're making, how fast you need them, and your material needs.

| Selection Criteria | Directed Energy Deposition (DED) | Powder Bed Fusion (PBF) |

|---|---|---|

| Part Size | Choose DED for large parts or components, as it has flexible build volumes and can work on existing substrates. | Choose PBF for smaller parts, as it's limited by the size of the powder bed (typically under 500 mm). |

| Complexity & Precision | Suitable for less intricate geometries or repairs; lower resolution but versatile for adding features. | Ideal for highly complex, detailed parts requiring high precision and fine features (e.g., lattice structures). |

| Material Requirements | Select DED for diverse materials (metals like titanium, steel, nickel alloys, or composites) and multi-material or graded deposition. | Best for powder-based metals (e.g., stainless steel, titanium, aluminium); limited to single-material parts. |

| Application Type | Preferred for repairs (e.g., turbine blades), cladding, or adding features to existing parts in aerospace, energy, or automotive. | Suited for new, intricate components like medical implants, aerospace parts, or prototypes with fine details. |

| Production Volume | Better for low-volume production, one-off parts, or repairs due to high deposition rates and flexibility. | Suitable for small to medium batch production of complex parts, but slower due to layer-by-layer processing. |

| Speed | Choose for faster deposition, especially for large parts or repairs (up to 5-10 kg/hour with wire-fed DED). | Select for slower, precision-focused builds where speed is less critical than detail. |

| Post-Processing Needs | Pick if minimal powder handling is preferred; may require machining for surface finish. | Choose if extensive powder removal and post-processing (e.g., for smooth finishes) are acceptable. |

| Material Efficiency | Opt for DED (especially wire-fed) for minimal waste, ideal for costly materials like titanium. | Select if recyclable powder waste is manageable, though some material loss occurs. |

| Cost Considerations | Choose DED for cost-effective repairs or large parts; wire-fed DED reduces material costs. | Better for high - precision parts where higher material and equipment costs are justified. |

| Equipment & Safety | Select for simpler handling (especially wire-fed) with lower safety risks and easier setup. | Choose if complex powder handling and safety protocols (e.g., for flammable powders) are feasible. |

Yes, and it's one of DED's biggest strengths. If only a portion of your part is worn or damaged, DED lets you rebuild just that area, saving you from scrapping the whole component. It's faster, more cost-effective, and helps extend part life.

| Feature | Wire-Fed DED | Powder-Fed DED |

|---|---|---|

| Feedstock Form | Uses continuous metal wire, typically 0.8-1.2 mm in diameter. | Uses fine metal powder, typically 20-150 µm in size. |

| Deposition Rate | Higher deposition rates (up to 5-10 kg/hour), ideal for large parts. | Lower deposition rates (0.1-2 kg/hour), suited for smaller, detailed components. |

| Material Efficiency | Near 100% material utilization, minimal waste due to precise wire melting. | Lower efficiency, with 10-30% material loss due to powder scatter or unmelted particles. |

| Material Cost | Generally lower cost, as wire is cheaper to produce and procure. | Higher cost due to expensive powder production and handling requirements. |

| Precision and Resolution | Lower resolution is better for large-scale or less intricate geometries. | Higher precision, ideal for complex, fine-featured components. |

| Safety and Handling | Safer and easier to handle, with no risk of powder inhalation or explosion hazards. | Requires strict safety protocols due to flammable and inhalable fine powders. |

| Equipment Complexity | Simpler feedstock delivery system, reducing setup and maintenance complexity. | More complex powder delivery systems, increasing equipment and maintenance needs. |

| Surface Finish | Smoother deposits are possible with consistent feed, though post-processing is often needed. | Rougher surfaces typically require more extensive post-processing. |

| Material Versatility | Limited to materials available in wire form (e.g., titanium, steel, and nickel alloys). | Wider material range, including composites and functionally graded materials. |

| Process Stability | More stable process with consistent wire feed, less sensitive to environmental factors. | More sensitive to airflow, humidity, and handling variations. |

Yes! Many systems now offer hybrid DED-CNC platforms and let you 3D print and machine the same part in one setup, saving time and ensuring tighter tolerances.

DED handles medium to large parts with ease. Build sizes can exceed 1 meter, which is ideal for structural components, shafts, molds, and more, especially compared to powder bed systems, which have tighter size limits.

Yes. DED supports more sustainable manufacturing by using only the material needed, reducing energy use, and making it easier to repair parts instead of replacing them. That’s a big win for circular manufacturing goals.

With m2nxt, you don’t just monitor - you understand, Optimized, and excel.