Produce or restore industrial-scale components with high-speed wire-arc deposition — cutting lead times, material waste, and production cost.

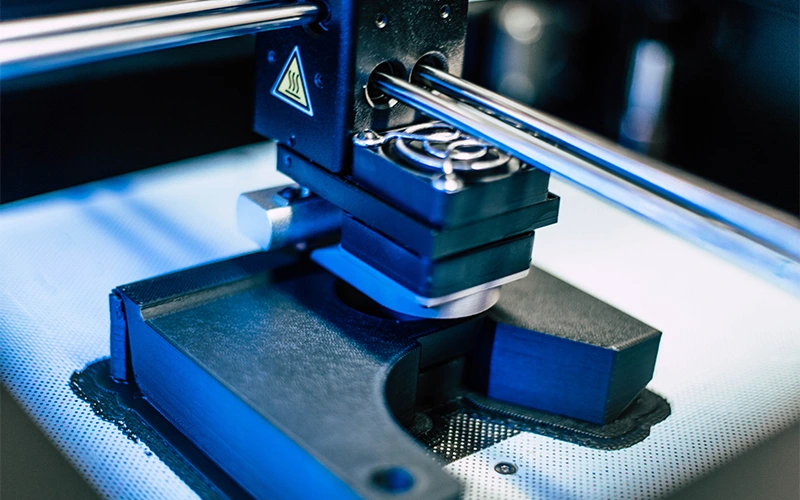

What is Electric Arc DED?

Electric Arc DED uses an electric arc to melt standard welding wire and deposit it precisely, layer by layer. This easy and big-scale way lets you make large metal parts fast, with next to no mess and almost no waste.

The method can work well with robot arms or big frame systems, making it great for work areas that rely on automation, like shipbuilding, heavy engineering, oil & gas, and tooling production.

If you're managing a shipyard, tooling shop, or heavy equipment line, Arc DED helps you overcome the most common and costly delays in metal part production and repair:

If you're working with large metal parts and need speed, simplicity, and cost-efficiency, Arc DED checks all the right boxes:

Arc DED can provide deposition rates of up to 10 kg/hour. You can build or repair large parts in a shorter time than it takes with powder or laser-based systems.

Arc DED uses off-the-shelf welding wire and not speciality powders. That means lower input costs, easier sourcing, and no dependence on niche suppliers.

Wire-fed deposition means you use nearly 100% of your material. Less waste. Fewer scrap parts. And no powder recovery or cleanup.

When the process and machine are set in properly, Arc DED parts aren’t just strong, they’re production-ready. They perform under stress, wear, and heavy use, just like cast or forged components.

The process integrates easily with robotic arms, gantries, or CNC systems. You can scale production without building a cleanroom or installing speciality equipment.

Arc DED is ideal for adding material where it’s worn, missing, or needs reinforcement. Instead of replacing the whole part, you just fix what’s needed, faster and cheaper.

No cleanrooms or powder chaos. Arc DED works with standard tools in standard environments - making it easy for your team to adopt, learn, and scale.

Trusted by manufacturers across sectors where precision, uptime, and traceability matter most.

Arc DED uses an electric arc to melt wire, and laser DED uses a laser to melt wire or powder. Arc DED is faster and more cost-effective for large, simple parts. Whereas laser DED offers higher precision but lower build rates.

Most standard welding wires are supported, like mild steel, stainless steel, Inconel, titanium, and others, depending on your process control.

No. Arc DED is built for large, robust components. If your application needs high detail or tight tolerances, laser powder DED or LMJ is a better fit.

Yes. It's often used to rebuild worn areas, restore geometry, or extend part life, without needing full replacement.

With the right setup, you can build parts several meters long, which is ideal for ships, machinery, or structural frames.

With m2nxt, you don’t just monitor - you understand, Optimized, and excel.