An Intelligent Manufacturing Execution System to manage and monitor the production process

What is i MES?

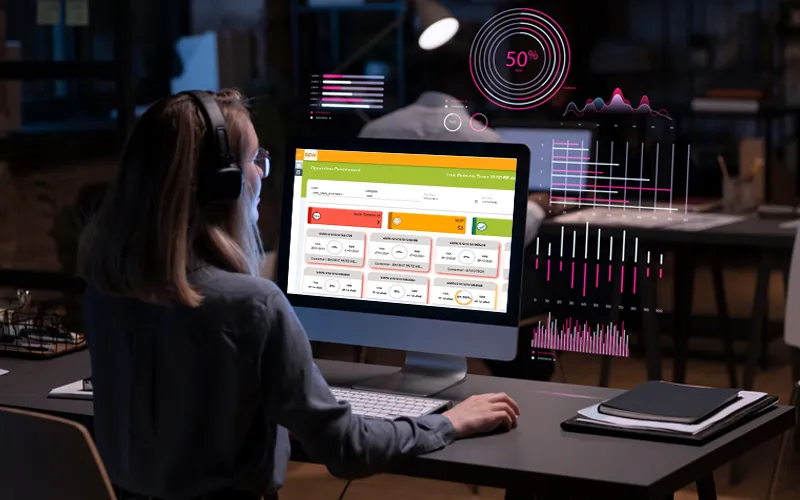

i MES (Intelligent Manufacturing Execution System) is your real - time command center for the shop floor.

The NO-Code Digital Process Assurance System can be easily adapted to any manufacturing process to ensure Traceability, Genealogy and will guide operators to view SOP and capture the field equipment data using an simple handheld Android Tablet.

With iMES, you can:

Built for real users. Designed for real-world shop floors. iMES brings structure, speed, and visibility to your production line from day one.

i MES is specially designed to work efficiently on any shop floor with minimal setup and training. And here’s how it functions.

As and when your operator works, it collects live data from sensors or manual inputs like torque, pressure, cycle times, etc., and stores it securely.

As soon as the shift starts, i MES shows simple, step-by-step tasks right on an Android device. No need to flip through papers or ask what’s next everything is shown clearly and visually.

Every part that’s fitted is automatically logged and linked to the job. So you always know what went where, and nothing gets misplaced.

From the first action to the last, i Mes keeps a clean digital record. If something goes wrong, you won’t need to search - the answer is already there.

Once a job is done, i MES pushes the data straight to your ERP system. No manual updates. No syncing delays. Just real - time accuracy, built-in.

Trusted by manufacturers across sectors where precision, uptime, and traceability matter most.

Not at all. i MES is built to work with manual, semi-automated, or legacy processes. It brings structure and traceability to any kind of setup, without needing full automation.

Yes. i MES is designed for the factories. It runs on Android and has a clean, task-focused interface. Most operators are up to speed within a day.

You can record torque, temperature, cycle time, operator inputs, and part IDs; basically, any process data you need. Data can be entered manually or pulled from field equipment.

Yes. i MES keeps a complete record of which part went where and when, so you always know if the right part was used at the right step.

Yes. i MES has a ready-to-use ERP interface and can integrate with most ERP systems for smooth data exchange. No double entry. No delays.

With m2nxt, you don’t just monitor - you understand, Optimized, and excel.