IRIS - An Industrial IoT Platform for Real - Time Shop Floor Visibility

What is IRIS?

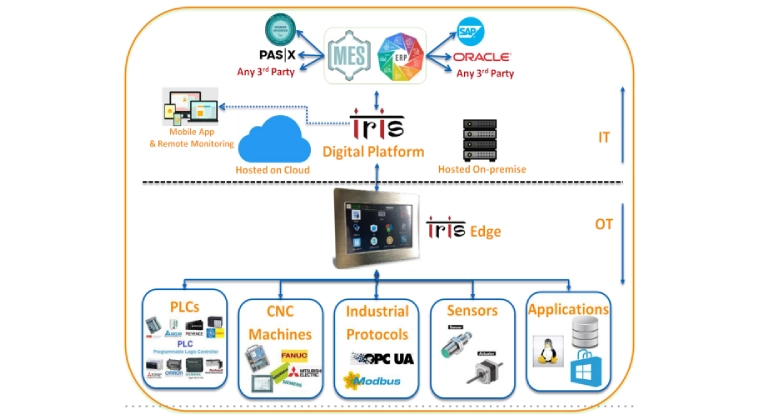

IRIS (Intelligent Reliable Innovative Seamless) is an Industrial IoT Platform that can connect and collect data from any modern or Legacy equipment to monitor the machine/asset performance in real time from anywhere through the Internet by accessing our IRIS Digital platform hosted on the Cloud or On-premises Server.

Real - Time visibility of Shop Floor with Digital Authentic Reports eliminating the shift-endmanual reports

IRIS Industry 4.0 - Simple, Scalable, and Built for Real - Time Monitoring of Manufacturing Shop Floor

Industry 4.0 is transforming factories with real - time data, connected systems, and smarter decision-making. IRIS brings these capabilities to your shopfloor without disrupting existing operations.

IRIS seamlessly connects your machines, automates data capture, and empowers your teams to act faster and with greater confidence.

IRIS integrates effortlessly with your existing infrastructure, delivering Real - Time visibility, actionable insights, and operational control where it matters most.

By unifying live machine data and human interactions, IRIS helps you reduce downtime, improve productivity, and enhance decision-making.

Take your first practical step into Industry 4.0 with IRIS - your smart , scalable, and ready-to-deploy solution for digital transformation in manufacturing.

IRIS brings live shop floor data to your screen, driving proactive decisions and zero downtime.

Trusted by manufacturers across sectors where precision, uptime, and traceability matter most.

Yes. IRIS is designed to work with both legacy and modern machines; there is no need to replace your existing setup. We retrofit your machines with smart interfaces to start capturing data right away.

No problem. IRIS uses edge computing to store data locally during downtime and syncs it back automatically, so you’ll never lose any data.

Not at all. IRIS is built to be simple and intuitive. Operators, supervisors, and managers can start using it with minimal training; we take care of setup and onboarding.

Yes. You can log into the IRIS dashboard from your mobile, tablet, or desktop and access it at any time from anywhere.

Absolutely. With real - time alerts, alarm tracking, and predictive maintenance tools, IRIS helps you detect problems early and respond faster by reducing unplanned stoppages significantly.

IRIS collects data from machines, materials, and production runs by giving you accurate job - level costing and early error detection for better quality control.

Yes. Whether you’re running one line or multiple plants, IRIS can be scaled and customised to your operations, now and in the future.

With m2nxt, you don’t just monitor - you understand, Optimized, and excel.