Catch errors early, cut rework, and ensure quality without slowing production.

What Are Measurement Solutions?

If your quality checks still rely on manual inspections, delayed reports, or isolated stations, you’re exposing your operation to unnecessary delays, higher costs, and risk to customer trust.

m2nxt Measurement Solutions are built to solve exactly that.

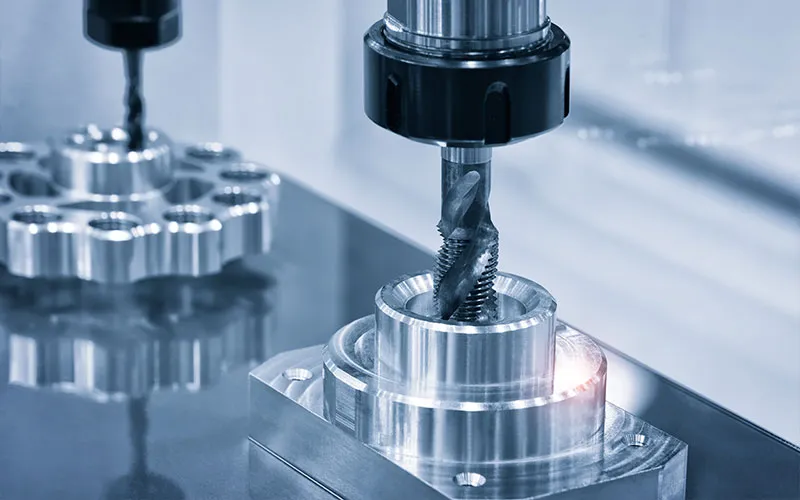

As a result, we can precisely control the tool offset in the machine tool and path program in robots

Think of it as quality control built directly into your line, running as fast as you do, catching every issue before it becomes a problem. Complete Q4.0 solution with SPC and SQC results

With early detection of the defects, you can decrease the scrap and rework and improve product quality.

No more inconsistent results. Robots deliver the same high - precision work every time, reducing errors and rework.

Inspecting the production line helps to speed up the entire process without introducing bottlenecks.

The digital records streamline audits and regulatory reporting, which makes the records traceable and easy to read.

The quality checks save on materials, labour, and warranty claims by catching errors early.

Trusted by manufacturers across sectors where precision, uptime, and traceability matter most.

Absolutely. Our systems offer micron-level precision and are perfectly suited for complex geometries and engineered components.

Never. Our solutions are operating inline, inspecting parts in real time without slowing your production line

Yes, our solutions will integrate easily with your CNC machines, ERP, MES, and quality management systems.

Not very hard at all. We provide training that is completely customised to your team and very intuitive software interfaces designed to be easy to learn and operate, getting your staff up to speed quickly.

Most of our custom measurement solutions will be delivered and up and running within 12-16 weeks, depending on complexity, with minimal disruption to your business operations.

Yes. This platform is modular and can be repeated or expanded across multiple locations commercially.

With m2nxt, you don’t just monitor - you understand, Optimized, and excel.