What is Metal Additive Manufacturing?

Metal additive manufacturing (3D metal printing) is revolutionising how critical components are produced or repaired - without the delays, waste, and constraints of traditional manufacturing methods.

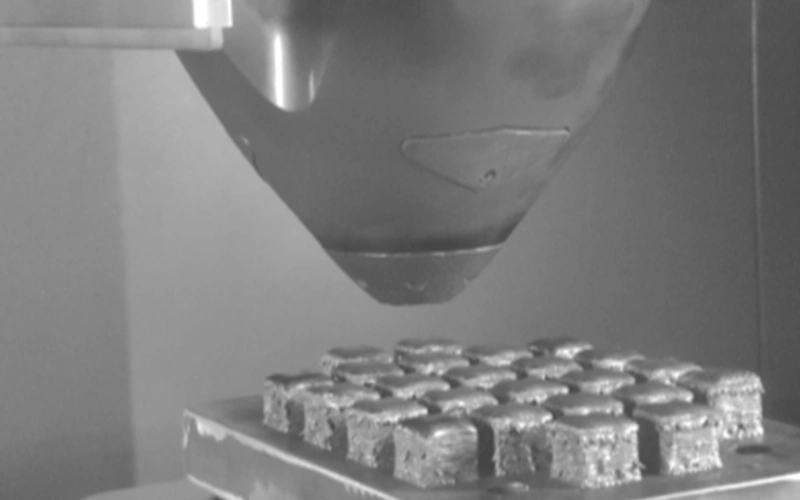

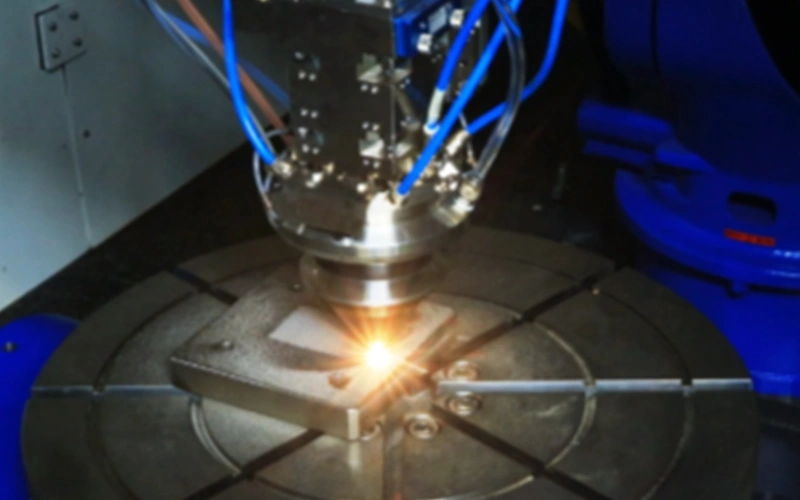

Instead of cutting or casting, this process builds parts layer by layer from a digital design using high-energy sources such as lasers or electric arcs. Technologies like Laser Directed Energy Deposition (LDED) and Liquid Metal Jetting (LMJ) allow for

Whether you're printing a new component or restoring a worn one, metal AM delivers production-grade quality with greater control, lower costs, and shorter lead times.

Built for Indian Industry. Backed by Global Standards.

At m2nxt, we are at the forefront of India’s 3D metal printing revolution. Our additive systems are engineered and manufactured locally, designed to meet global performance benchmarks.

We’ve also pioneered advanced LDED platforms - Laser Wire, Laser Powder, and Electric Arc DED, each tailored for specific material types, deposition needs, and part geometries.

When conventional manufacturing holds you back with tooling delays or limited design options, metal 3D printing helps you move forward. You can print fully functional metal parts with complex geometry faster, in-house, and without reworking designs to fit the process.

View More

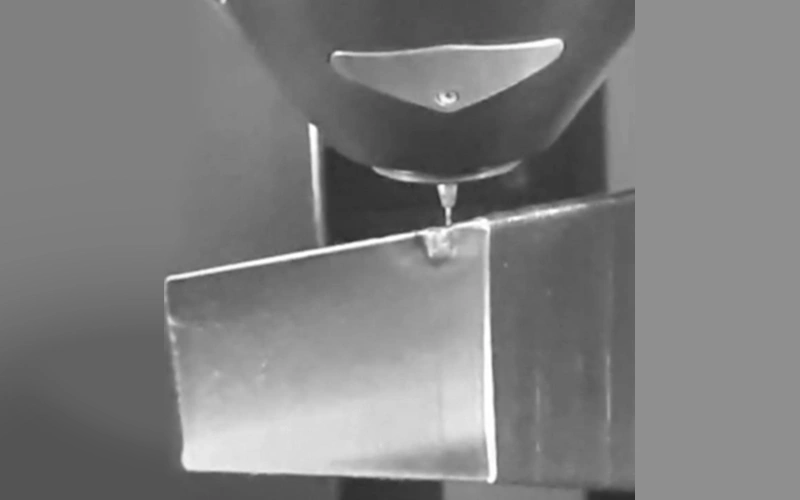

Don’t replace an entire part just because a small section is worn. Our systems help you repair exactly what’s needed—saving time, cost, and material, while keeping performance intact.

View More

Need better wear or corrosion resistance without replacing the whole part? Our machines let you add just the right layer of metal where it’s needed, which cuts downtime and extends part life, even in harsh conditions.

View More

If you are exploring materials, validating designs, or testing new processes, our systems are development-focused research & development systems. Our 3D metal printing machines are used in labs, institutes, and R&D teams throughout all sectors.

View MoreIARC program

Join m2nxt Solutions Pvt. Ltd. in revolutionizing India's additive manufacturing landscape through our Industry-Academia Research Collaboration (IARC) Program!

This program is tailored for M.Tech students from top-tier institutes (IITs, NITs, VIT, SRM, BITS Pilani, etc.), to empowers the next generation of innovators to drive India's growth in metal additive manufacturing. By training participants in advanced technologies and offering hands-on experience with state-of-the-art Directed Energy Deposition (DED) machines at our modern Bangalore facility, m2nxt is building a skilled workforce to drive India’s technological progress.

Through this initiative, we align with the Self-Reliant India mission, empowering the nation’s talent to contribute to the Indian manufacturing revolution and fulfill the vision of a technologically advanced India. Collaborate with expert application engineers, receive mentorship from our Additive Manufacturing Department, and engage in impactful 3 to 9 months internship/research projects that bridge academia and industry.

As a result of the program’s outcomes, participants can earn a prestigious certificate of completion, gain valuable industry exposure, and explore potential career opportunities with m2nxt. Exceptional candidates may be considered for future application roles. Be a part of India’s additive manufacturing revolution—apply now through your institute’s nomination!

Future-ready tech like EB-DED, hybrid WAAM, and EHLA to help you build bigger, move faster, and cut complexity — all without compromising on quality.

Yes. In fact, our machines are being used to print end-use, industrial-grade parts for demanding sectors like aerospace and defence.

We can normally complete the setup of a system and training for your operators in 2-3 weeks, depending on how big your facility is.

Not at all. We train your team, even if they’re new to additive manufacturing.

Absolutely. DED is built for repair and refurbishment.

Yes, our systems are designed to integrate with most manufacturing lines.

With m2nxt, you don’t just monitor - you understand, Optimized, and excel.