Our VMC & HMC workholding solutions help you cut setup time, run more parts, and keep production predictable.

What Are VMC & HMC Workholding Solutions?

When your fixtures don't fit your job, or worse, your machine - you lose more than just time. You lose precision, productivity, and profitability.

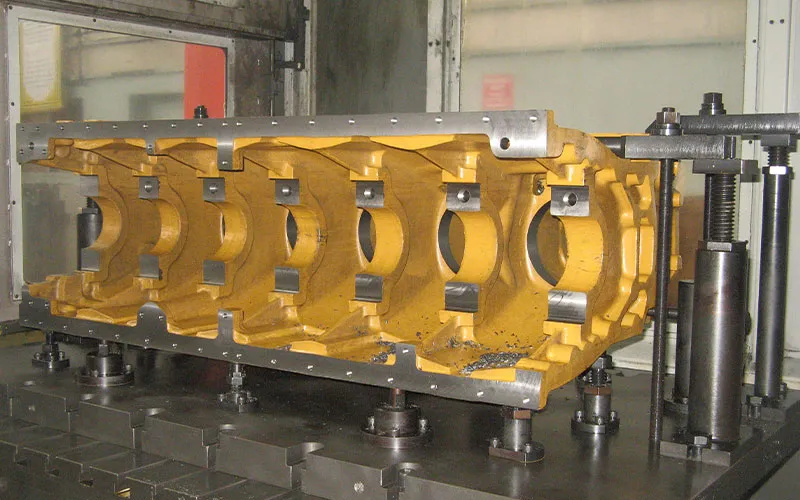

At m2nxt, we design and deliver custom workholding systems for VMC and HMC that are made to match your parts, your cycle times, and your floor realities. Whether you're dealing with high-mix, low-volume jobs or repeat batches, our solutions eliminate guesswork and clamp-time headaches.

They're engineered for your exact workflow - so setups are faster, accuracy stays consistent, and your machines keep cutting without delays.

Our fixtures are designed to make the tooling fit your parts and machines efficiently. You can expect faster changeovers and higher outputs per shift.

No more sloppy fits or misalignments. Our tooling holds fixtures in a fixed position, allowing you to hold tighter tolerances and thereby reducing rework

Are you running different batches or switching parts? Our modular designs allow you to reconfigure your setup without the need to retool the entire line.

Whether you have VMC or HMC, we are able to design a solution that will plug right into the machines, with no need for retrofits or compromises.

We are by your side from initial designs through to delivery and on-site setup. Because the real win is not just getting it right on paper. It is important to make sure it works on your shop floor

Trusted by manufacturers across sectors where precision, uptime, and traceability matter most.

If you spend too long setting up each job, or if you are constantly adjusting clamps during a job, custom solutions are most beneficial in saving you time and most advantageous if you have any kind of repetitive job.

No. Our fixtures are designed to work with your machine, regardless of the machines you have. We have customers using BFW,indian ,European and Japanese VMCs & HMCs, etc as well as other Indian and global machine brands.

Generally, most lead times are 12-16 weeks. We do have expedited services with standard builds as well. We also support rush requests.

Yes, for sure. We build workholding for both high-volume production and small-volume R&D or prototype runs.

Yes. We provide on-site setup and training anywhere in India to allow equipment to operate as expected from day 1.

With m2nxt, you don’t just monitor - you understand, Optimized, and excel.